Understanding ESD Flooring Standards and Compliance

Through years of consulting work with manufacturing facilities, I've seen firsthand how critical proper ESD flooring standards are for protecting sensitive electronic components and maintaining regulatory compliance. The difference between adequate and exceptional flooring solutions often comes down to understanding the technical requirements.

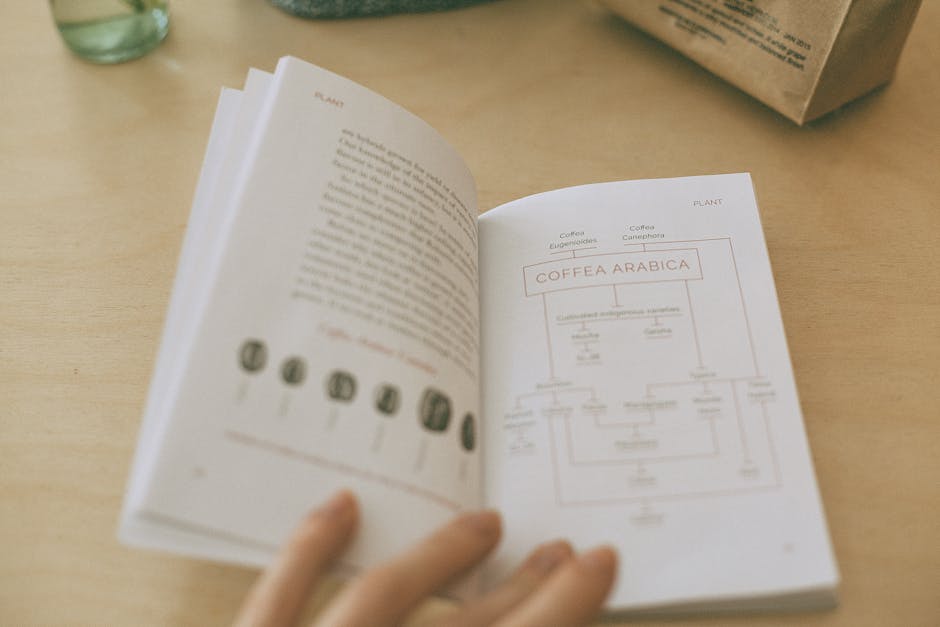

As the EOS/ESD Association explains, proper ESD flooring must meet ANSI/ESD S20.20 standards to effectively control electrostatic discharge in manufacturing environments. These standards ensure that floors maintain resistance levels below 1.0 x 10⁹ ohms, which we've found especially critical when protecting sensitive electronic components.

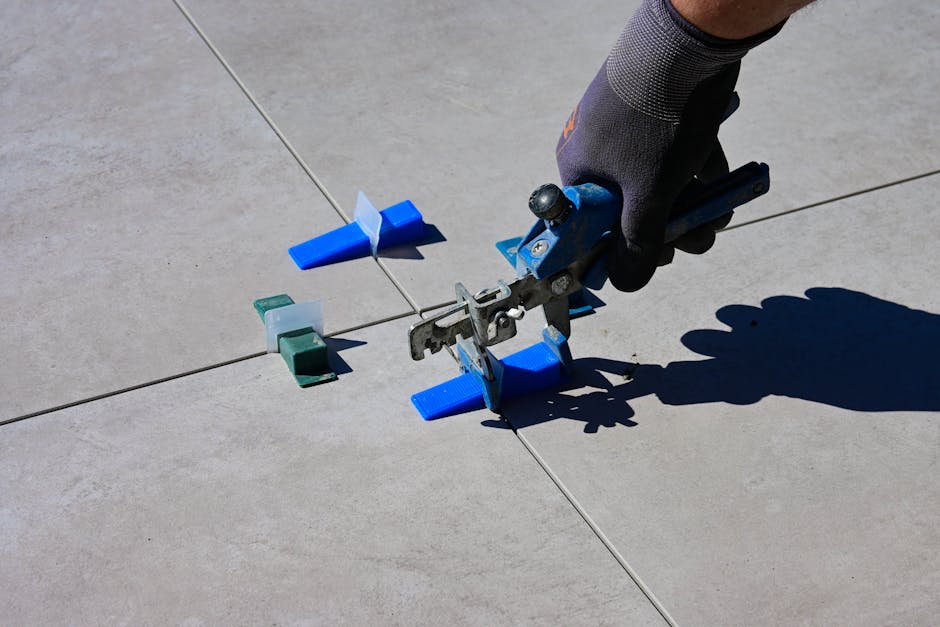

In my experience evaluating industrial facilities, the most successful implementations combine technical compliance with practical usability. Facilities that invest in quality ESD flooring systems see measurable improvements in product quality and reduced equipment damage from electrostatic discharge events.

The key specifications to understand include surface resistance measurements, grounding system requirements, and periodic testing protocols. When I work with facility managers, I emphasize that compliance isn't just about meeting minimum standards - it's about creating a safe, productive environment that protects both personnel and equipment.