Expert-Evaluated Industrial Flooring Projects

As construction standards specialists and professional consultants in the industrial flooring sector, we've had the opportunity to evaluate and document numerous high-quality ESD flooring installations across manufacturing facilities, cleanrooms, server rooms, and electronics assembly environments. This portfolio showcases the caliber of work we look for when recommending industrial flooring contractors to our clients.

Our expertise in contractor evaluation and building codes enables us to recognize truly exceptional installations that meet stringent electrostatic discharge control standards. Each project featured here demonstrates the technical precision, quality workmanship, and attention to detail that we consider essential for protecting sensitive electronic equipment and maintaining workplace safety in industrial environments.

Electronics Manufacturing Facility

This installation showcases professional-grade interlocking anti static floors designed for high-volume electronics assembly operations. The precision installation ensures consistent resistance levels across the entire manufacturing floor, protecting sensitive components from electrostatic discharge while maintaining durability under heavy foot traffic and equipment movement.

Clean Room Application

High-performance factory esd floor system installed in a pharmaceutical cleanroom environment. This installation demonstrates the intersection of ESD protection and contamination control requirements.

Server Room Protection

Professional interlocking esd carpet installation providing both static control and aesthetic appeal in a data center environment. The modular design enables easy replacement of individual tiles without disrupting operations.

Manufacturing Excellence

Heavy-duty factory conductive floor designed for industrial environments requiring robust ESD protection. This installation handles forklift traffic while maintaining consistent electrical properties.

Modular Tile System

Versatile interlocking esd tile configuration offering flexibility for evolving facility layouts. The raised floor design accommodates power and data distribution infrastructure.

Featured Project: High-Tech Electronics Assembly Facility

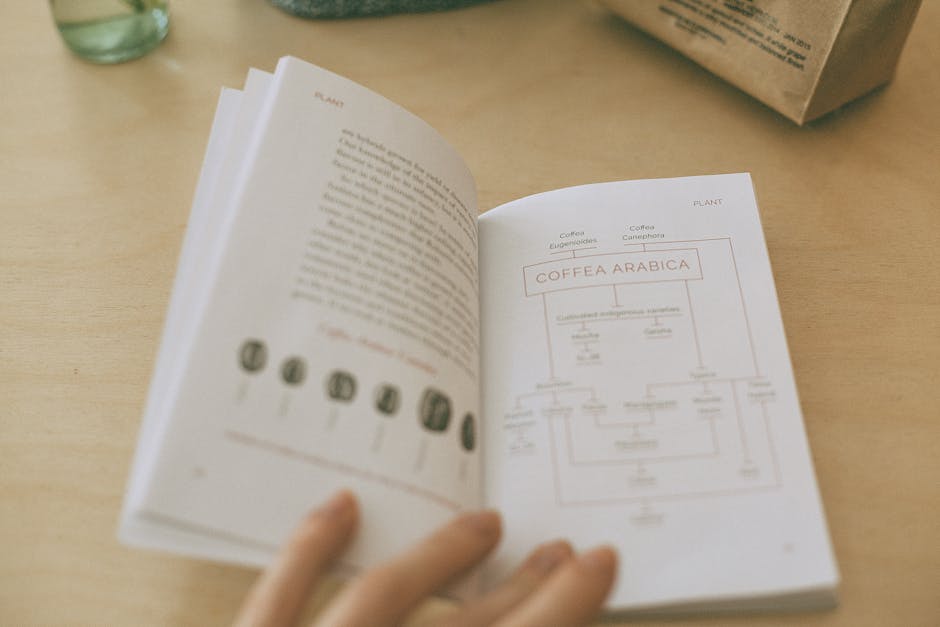

Project Overview: Comprehensive ESD Flooring System

This flagship installation represents the gold standard in industrial ESD flooring systems. The project involved outfitting a 50,000 square foot electronics assembly facility with a complete anti-static flooring solution designed to protect sensitive components valued in the millions of dollars.

Project Requirements: The facility manufactures precision electronic components for aerospace and medical device applications, requiring strict adherence to ESD control standards. The flooring system needed to provide consistent static protection across multiple work zones while accommodating heavy equipment, frequent material handling operations, and stringent cleanroom protocols in designated areas.

Installation Excellence: What distinguishes this installation is the meticulous attention to grounding grid integration, seamless transitions between different flooring types, and comprehensive documentation of resistance measurements across the entire facility. The contractor demonstrated exceptional understanding of both electrical grounding principles and the practical requirements of a working manufacturing environment.

Performance Validation: Post-installation testing confirmed surface resistance values consistently within the specified range of 2.5 x 10⁷ to 1.0 x 10⁹ ohms across all tested locations. The system maintains these values even in high-traffic areas after months of operation, demonstrating both quality materials and proper installation technique.

Project Categories & Specializations

Electronics Manufacturing

PCB assembly, semiconductor handling, component storage facilities requiring precise ESD control and consistent resistance levels throughout production areas.

Data Centers & Server Rooms

Critical infrastructure environments where equipment protection and operational reliability depend on proper static control flooring systems.

Cleanroom Environments

Pharmaceutical, biotech, and precision manufacturing facilities requiring both ESD protection and contamination control properties.

Warehouse & Distribution

Large-scale storage facilities handling electronic components, requiring durable flooring that maintains ESD properties under heavy equipment traffic.

Aerospace Applications

Specialized installations meeting aerospace industry standards for avionics assembly, testing facilities, and sensitive equipment handling areas.

Laboratory Settings

Research and testing environments where static-sensitive instruments and materials require comprehensive ESD flooring protection.

Professional Assessment Criteria

When evaluating industrial flooring installations for inclusion in our portfolio, we apply rigorous standards based on our expertise in construction standards and quality workmanship. Each project must demonstrate excellence across multiple dimensions:

Technical Compliance

Verified adherence to ANSI/ESD S20.20 standards, proper grounding grid installation, documented resistance measurements, and comprehensive system testing confirming electrical performance meets or exceeds specifications.

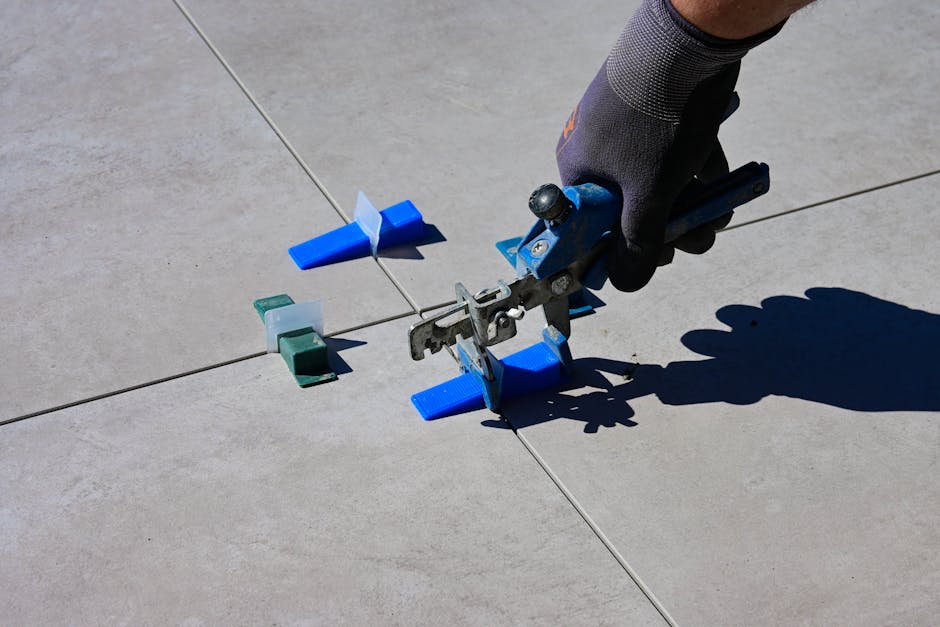

Installation Quality

Attention to detail in seam alignment, uniform adhesive application, proper subfloor preparation, seamless transitions between flooring types, and meticulous finishing work at walls and equipment interfaces.

Material Selection

Appropriate flooring products chosen for specific application requirements, balancing ESD performance, durability, chemical resistance, maintenance requirements, and aesthetic considerations for the facility.

Long-Term Performance

Systems that maintain consistent electrical properties over time, resist wear and damage from daily operations, and continue protecting sensitive equipment throughout their expected service life.

Additional Project Examples

Medical Device Manufacturing

Specialized ESD flooring installation in medical device assembly facility requiring FDA compliance and stringent quality control. The installation demonstrates proper integration with cleanroom protocols while maintaining reliable static protection.

Telecommunications Hub

Large-scale ESD flooring project protecting critical network equipment and fiber optic infrastructure. The installation showcases expertise in raised floor systems with integrated cable management and environmental monitoring access.

Automated Manufacturing

Robotic assembly facility featuring durable conductive flooring capable of withstanding continuous automated equipment traffic while providing consistent ESD protection across the production line.

Evaluating Industrial Flooring for Your Facility?

Leverage our expertise in construction standards and contractor evaluation to ensure your industrial flooring project meets the highest quality benchmarks. We provide professional consulting services for facility managers, engineers, and project owners seeking expert guidance on ESD flooring systems.

Schedule Professional Consultation